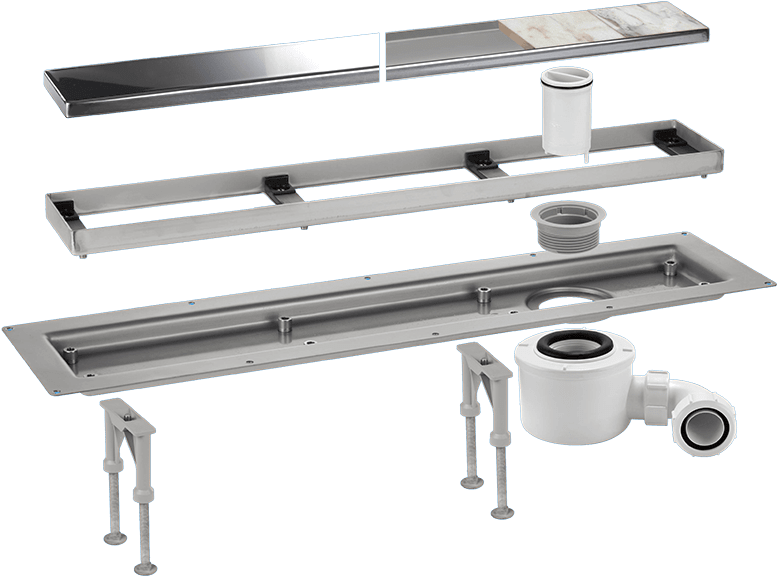

Everything you need in one box!

Every McAlpine Channel Drain comes complete with body, cover plate, trap with UK outlet and accessories, so ordering could not be simpler. McAlpine Channel Drains achieve a flow rate of 54 litres per minute when tested in accordance with Clause 5 of BS EN 274 2:2002.

CD1000

Standard Channel Drains

Watch our video giving an overview of our channel drains and how they are installed.